Ross had earlier visited an Army vendor’s facilities where they were developing composite materials and she recalled, “An interesting composite material where they were taking silicon and metal and essentially fusing it together.

This is a significant step forward in manufacturing and design.”ĭr.

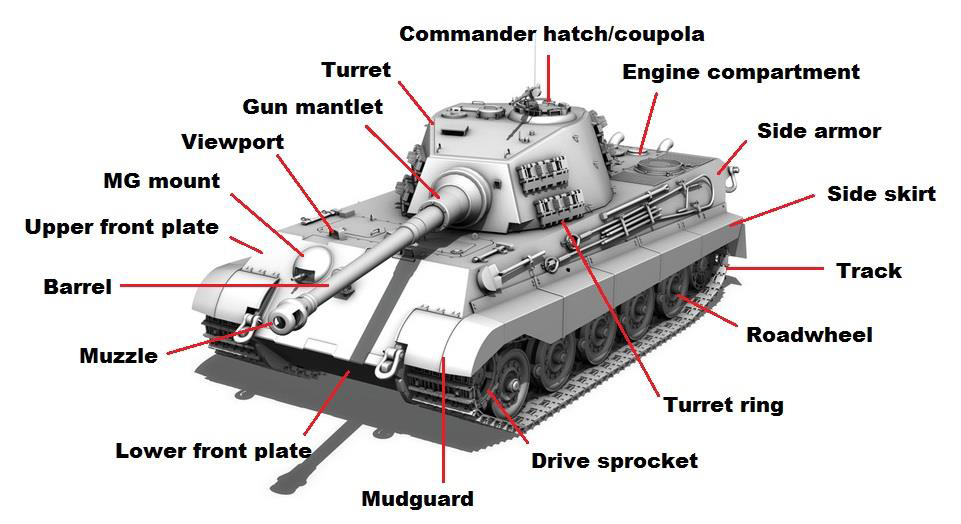

Ross, a deputy assistant Army secretary for strategy and acquisition reform explained that “Additive manufacturing, composite materials, and machine learning have already brought a new industrial revolution to private industry. McCarthy said, “We’re already doing it in 2021, but we needed to get more aggressive so we could have a comprehensive approach.”ĭr. The US Army initiative will put strategic guidance out to the service and industry partners to indicate the number of resources, people and funding into additive manufacturing technology the US Army will be investing in its future plans.Īs per a statement to Army Times, Army Secretary Ryan D. It believes that additive manufacturing technology will be a faster and cheaper way to repair & service all types of equipments.Īn expeditionary capability to print parts will enable US military forces to extend the range of a brigade combat team. US Army has announced its plans to use additive manufacturing technology to produce replacement parts on-site, for tanks and other equipment back into the battlefield. The M-1 tank has two main parts: a pivoting gun turret and a tracked hull.Above: US Army’s M1 Abrams Tank/Image Credit: US Army The turret is an armored structure supporting one or more guns - typically a heavy cannon and a couple of machine guns. The hull's job is to transport the top portion of the tank, the turret, from place to place. The hull is the bottom portion of the tank - the track system and an armored body containing the engine and transmission. Additionally, the track has heavy tread that digs into muddy surfaces, and it never goes flat like a tire. A car grips the ground with only the bottom portion of four tires, but a tank grips it with dozens of feet of track. Tracked vehicles can move easily over rough terrain because the track makes contact with a wide area of the ground. The internal combustion engine made tracked military vehicles feasible. Earlier tracked vehicles weren't practical in battle because their steam engines were too cumbersome and unreliable. The tank's wheels ride along the moving track, just like the wheels in a car run along the road.

The tank engine rotates one or more steel sprockets, which move a track made up of hundreds of metal links. Caterpillar tracks work on the same principle as a conveyer belt.

0 kommentar(er)

0 kommentar(er)